In today’s competitive market, manufacturing companies are up against operational chaos. This article will explore the common challenges facing the manufacturing sector and show how Odoo 18 is the answer. We’ll look at real-life examples and give you a clear roadmap to transform your operations from chaos to complete control and scalability.

Are you short on time?

Key Points

- Manufacturing companies face challenges like operational chaos, disjointed systems, and poor inventory management, which hinders efficiency and competitive edge.

- Odoo 18 is an all-in-one solution that unifies all business operations on one platform, streamlines processes, and gives real-time data visibility.

- A successful implementation of Odoo involves a structured approach, including assessing current challenges, partnering with an expert, and focusing on continuous improvement.

Are You Experiencing Operational Chaos?

Key Challenges in Modern Manufacturing

Operational chaos is the bane of many manufacturing businesses today. Disjointed systems, inefficient processes, and poor inventory management can cause big disruptions and increased costs. These challenges not only affect the bottom line but also hinder a company’s ability to meet customer demands and stay competitive in the market.

Manufacturers struggle to manage inventory effectively, resulting in either excess stock or stockouts. This section will break down the challenges faced by manufacturers into three key areas: disjointed systems and data silos, production bottlenecks, and the high cost of poor inventory management.

Disjointed Systems and Data Silos

Disjointed systems and data silos are a big problem for many manufacturers. When data is scattered across different spreadsheets and manually entered into different systems, it leads to human errors and inconsistencies. This fragmentation makes it impossible to get a single view of the entire business operation, creating barriers to decision-making and complicated record-keeping.

Poor communication and data flow between sales, production, and finance teams makes it worse. Without real-time inventory visibility across warehouses, manufacturers delay decision-making processes, hindering operational efficiency. Isolated data repositories prevent seamless collaboration, resulting in inefficiencies and production bottlenecks.

Production Bottlenecks and Inefficiencies

Production bottlenecks and inefficiencies can kill a manufacturing operation. Complex workflows that are hard to manage and track can cause production delays. Frequent production downtime due to scheduling conflicts or material shortages can stop operations and increase operational costs.

Insufficient resource allocation and slow procurement and work order processing make it worse. A lack of clear instructions for workers on the shop floor results in errors and delays. These issues not only prolong lead times but also create big inefficiencies that increase costs.

The High Cost of Poor Inventory Management

Poor inventory management can be costly. Manufacturers lose money due to excess inventory, obsolescence, or stockouts. Inaccurate demand forecasting leads to overproduction or underproduction, further exacerbating losses.

Without a centralized system for inventory control, including lot and serial number tracking, manufacturers spend too much time on manual inventory counts and reconciliations. Poor inventory management not only loses money but also damages customer satisfaction due to delayed order fulfillment.

Odoo 18: The All-in-One Solution for Manufacturing Control

Odoo 18 is the solution manufacturers have been waiting for. Odoo 18 integrates all business functions into one platform for manufacturing, inventory, sales, accounting, and CRM. This all-in-one approach ensures all aspects of the business are connected, eliminating data silos and giving real-time visibility across the entire operation.

New features in Odoo 18, such as flexible project integration directly into manufacturing orders, allow manufacturers to enhance traceability and streamline their workflows.

The next sections will show how Odoo 18:

- Unifies operations

- Optimizes the production floor

- Masters planning and scheduling

- Enables data-driven decision-making

Unify Your Entire Operation on One Platform

Odoo 18 unifies all business operations on one platform, providing 365-degree real-time visibility into the entire business from one dashboard.

It integrates:

- Manufacturing

- Inventory

- Sales

- Accounting

- CRM

Odoo 18 eliminates data silos and automates information flow between departments, creating one source of truth. The result is better communication, faster decision-making, and greater operational efficiency.

Streamline and Optimize Your Production Floor with Odoo 18

Odoo 18 introduces new features that streamline and optimize production processes. One of the key features is the ability to link manufacturing orders directly to projects for traceability. Manufacturers can also add components or steps to a manufacturing order in real-time without stopping production, allowing for more flexibility and efficiency.

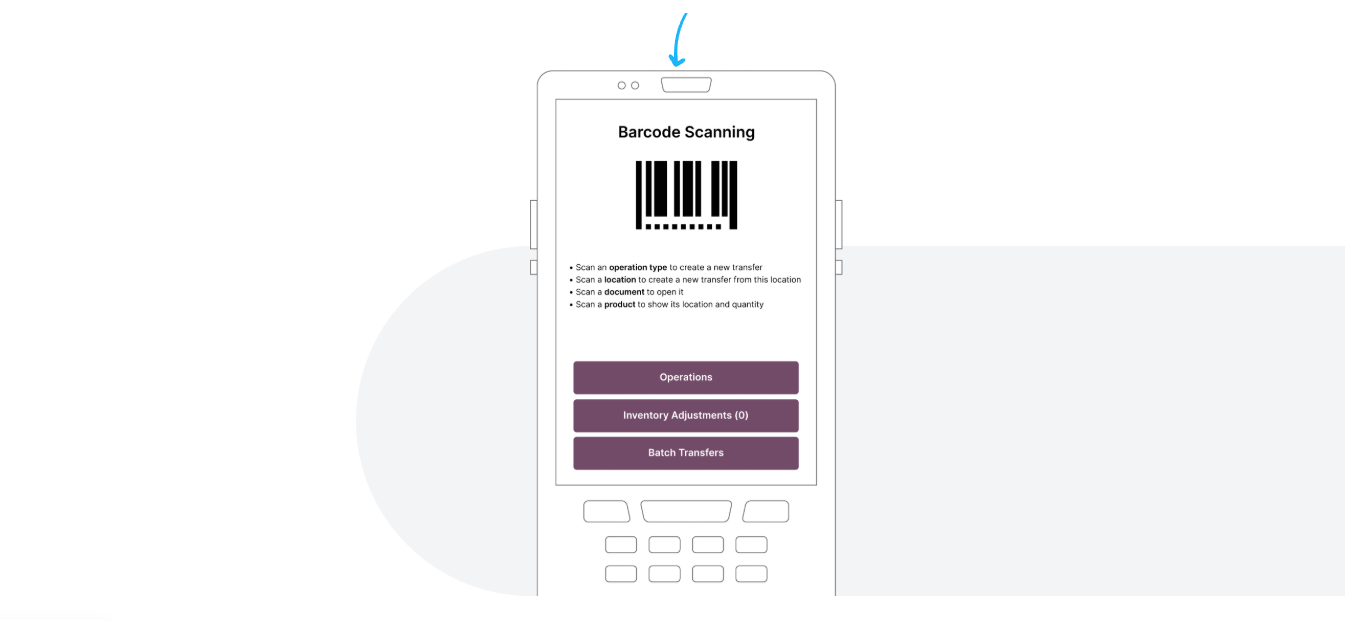

Automating Bill of Materials (BoM) calculations and work order generation simplifies the manufacturing process. Barcode scanning for shop floor control and material tracking makes production runs smooth and efficient.

Key features include:

- Automating Bill of Materials (BoM) calculations

- Automating work order generation

- Barcode scanning for shop floor control

- Barcode scanning for material tracking

Master Planning and Scheduling

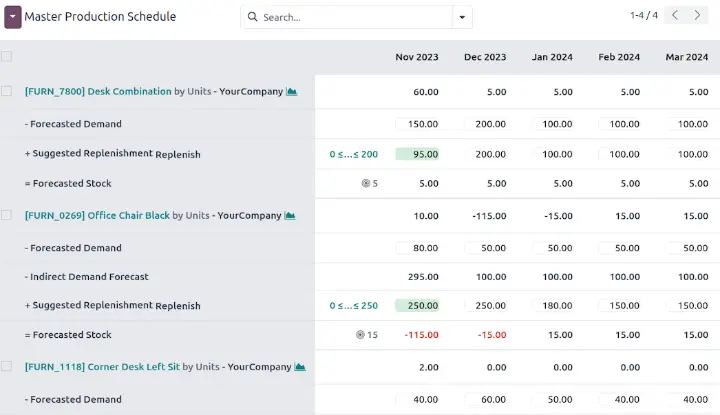

Odoo 18’s Master Production Schedule (MPS) has advanced planning and lot-sizing capabilities, allowing manufacturers to forecast demand better and optimize inventory levels. With better Gantt view navigation, users can manage complex schedules with improved zoom and scrolling chart features.

The new planning capabilities allow for better resource allocation across production schedules, enabling manufacturers to dynamically adjust to changes in demand. This flexibility ensures production runs are planned efficiently, reducing lead times and costs.

Data-Driven Decision-Making with Analytics

Odoo 18 empowers manufacturers to make data-driven decisions with its analytics features. Users can compare estimated vs actual production costs on analysis reports to identify inefficiencies and areas for improvement. Tracking key manufacturing KPIs helps measure performance and drive continuous improvement.

Customizable reports allow manufacturers to analyze operational performance, providing real-time financial insights for businesses to gauge their profitability instantly. This level of visibility allows manufacturers to make informed decisions to optimize their operations.

Real-World Transformations: Odoo Manufacturing Success Stories

Odoo has transformed many manufacturing companies, allowing them to streamline their processes and be more efficient. In this section, we’ll look at two real-world success stories that show the tangible benefits of implementing Odoo in manufacturing operations.

Case Study: Industrial Group

An industrial group had major operational bottlenecks and slow inventory reconciliation due to siloed, manual systems. Implementing a fully integrated Odoo ERP unified their complex manufacturing and inventory workflows. The results were impressive: a 40% reduction in production lead time and 60% faster inventory reconciliation.

Better collaboration across departments created a more cohesive operational environment, reduced order processing errors, and improved customer satisfaction.

Case Study: Welding Machine Manufacturer

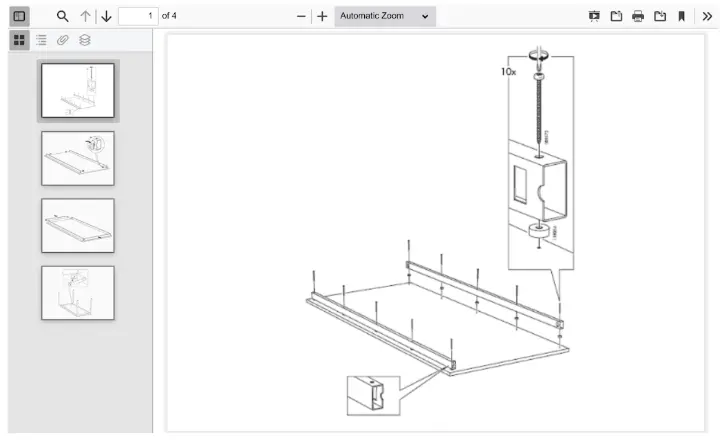

A welding machine manufacturer had a complex production process with over 15,000 components and needed to improve after-sales service. Deploying Odoo’s manufacturing, inventory, and repair modules created a seamless, end-to-end operational flow. This integration allowed full traceability from raw materials to finished goods and improved repair and service operations.

They reduced waste and improved productivity with real-time updates and tracking of components. Odoo’s customizability allowed them to tailor the software to their specific needs, and it’s now a crucial tool to manage their inventory.

Your 4-Step Roadmap to a Scalable Future with Odoo

Implementing Odoo can improve operational efficiency and scalability in manufacturing, but a structured approach is key to aligning the system with business objectives. This section provides a practical roadmap to implement Odoo successfully.

Step 1: Assess Your Current Pains and Future Goals

The first step to implement Odoo is to:

- Assess your current operational challenges and define future goals.

- Document your biggest operational bottlenecks.

- Clearly define what success looks like for your business (e.g., reduce lead times or cut inventory costs).

- Engage key team members from every department in this process to get a full understanding of the challenges.

This step sets the foundation for defining strategic goals for your Odoo implementation, ensuring the system aligns with your business objectives.

Step 2: Find an Expert Odoo Implementation Partner

Selecting the right Odoo implementation partner is key; choose a partner that can customize the system to your business processes.

Look for:

- A certified Odoo partner with experience in the manufacturing industry.

- Case studies that demonstrate their expertise.

- References to ensure they have the necessary experience.

A partner’s industry experience can greatly enhance the effectiveness of your Odoo implementation, ensuring the system meets your specific workflows and requirements.

Step 3: Plan for a Smooth Implementation and Transition

To ensure a successful Odoo implementation:

- Work with your implementation partner to create a clear project roadmap with distinct phases and timelines. This will minimize disruption and help your team navigate the transition smoothly.

- Prioritize clean data migration to ensure a successful launch.

- Invest in comprehensive employee training to drive user adoption and maximize your ROI.

Step 4: Drive Continuous Improvement and Growth

Use Odoo’s flexibility to adapt and scale as your business grows. To get the most out of Odoo:

- Use Odoo’s reporting tools to review performance against your goals regularly.

- Look for new opportunities to automate and optimize processes within the system.

- Evaluate performance metrics to make informed decisions for ongoing improvements in Odoo.

Focus on continuous improvement by using Odoo's data to optimize your processes and adapt as your business grows.

Conclusion

Manufacturers struggling with operational chaos can find a solution in Odoo 18. From unifying disparate systems and optimizing processes to mastering planning and scheduling and making data-driven decisions, Odoo 18 has what manufacturers need to transform their operations. The real-life examples of an industrial group and a welding machine manufacturer prove the tangible benefits of implementing Odoo.

By following a structured roadmap—assessing your current pains, finding the right implementation partner, planning a smooth transition, and driving continuous improvement—manufacturers can get the most out of Odoo 18. Upgrade to Odoo 18 and start your journey to operational excellence and scalable growth.

Frequently asked questions

Yes, Odoo is a good choice for small manufacturing businesses due to its scalability, user-friendly interface, and cost-effective modular design.

It’s accessible and practical for companies looking to enhance their operations.

Odoo effectively manages complex Bills of Materials by supporting multi-level BoMs, providing flexibility with optional components and by-products, and allowing for alternative components. This ensures you have full control over your manufacturing processes.

Yes, Odoo can integrate with your existing shop floor machinery through its IoT Box and API, allowing for real-time data collection and monitoring.

This integration enhances your operational efficiency and data-driven decision-making.

Odoo 18 improves manufacturing with a stronger Master Production Schedule (MPS), on-the-fly order modifications, direct linking of manufacturing orders to projects, better cost analysis, and enhanced mobile accessibility.

These features make it more efficient than previous versions.

Odoo 18 improves production by making processes more efficient with real-time adjustments, automated BoM calculations, barcode scanning, and improved planning and scheduling capabilities.